Client Overview

Our client, a large kitchenware manufacturer based in Peru, was looking to expand its production capacity, increase productivity and meet individual requirements in order to meet the diversified customisation needs of the market.

The Challenge

For the kitchenware industry, it is a huge challenge to cut complex kitchenware moulds, stainless steel cutlery in a single operation with smooth and burr-free edges, and to efficiently cut different materials such as stainless steel, carbon steel, aluminium and other commonly used metals in the kitchenware industry.

The Solution

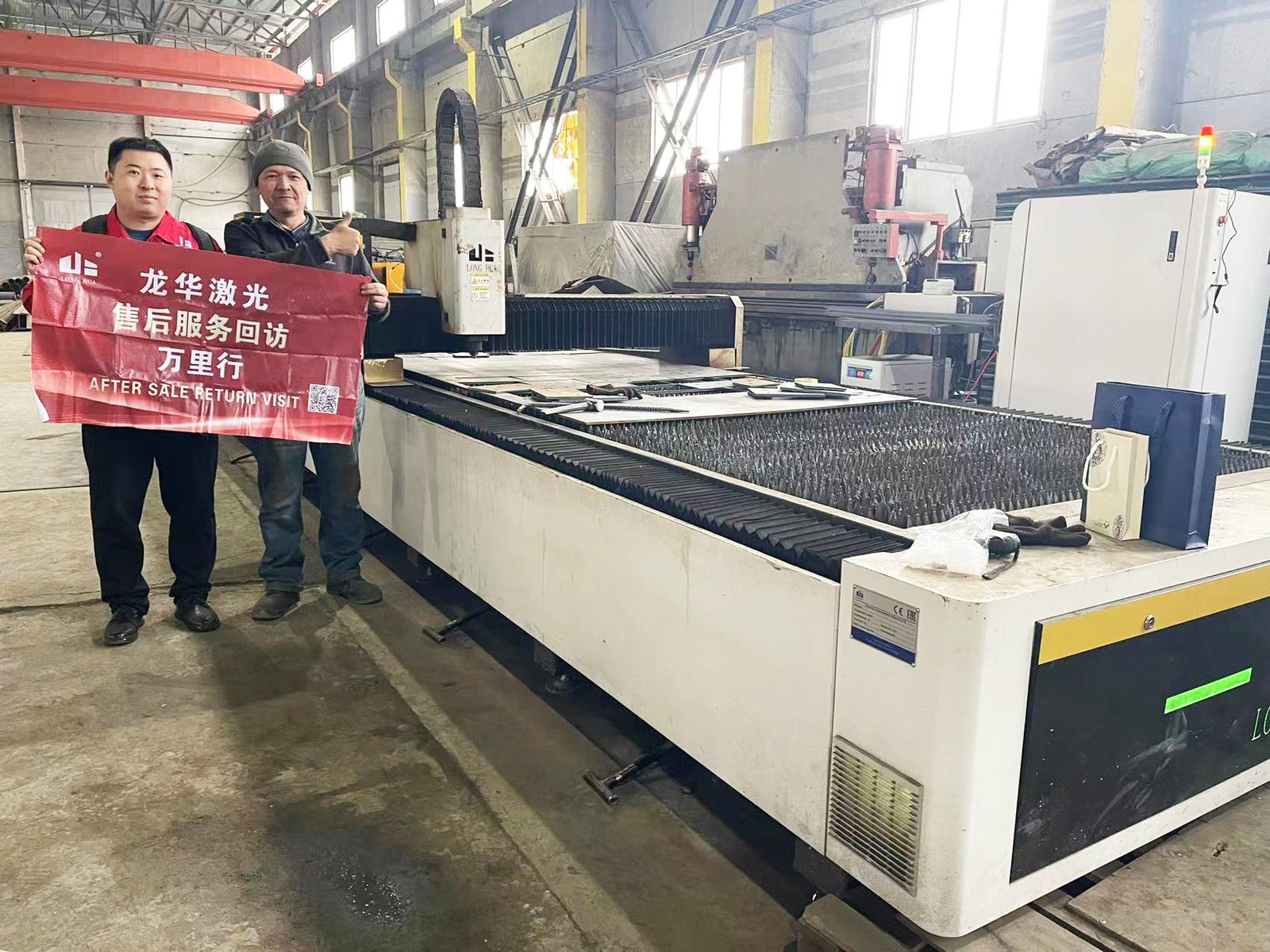

Through in-depth communication with the customer, understand the customer’s needs, take the customised solution for the customer; provide the customer with a Spanish operating page, 3kw cutting power, cutting stainless steel thickness up to 20mm, and the edge of the cutting smooth, one-time completion, to meet the customer’s requirements

Achievements

Saved 35% cost compared to imported European equipment, we also provide customers with free cutting parameter packages for the kitchenware industry (including local material database), solved the customer’s production efficiency problems, and greatly increased production capacity.